Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer:连接器 Posted time {{1543286740000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:379

According to the National Bureau of Statistics, China's industrial robots increased by 33.7% in the first five months of 2018. It can be seen that the proportion of industrial robots in industrial production is constantly increasing, and the market demand is increasing year by year. In the future, the replacement of labor by industrial robots becomes an irreversible trend.

Industrial robots are also undergoing continuous iterative upgrades of technology, which will inevitably bring about huge changes in the field of lines and connectors, which will bring revolutionary prospects for the entire connected device.

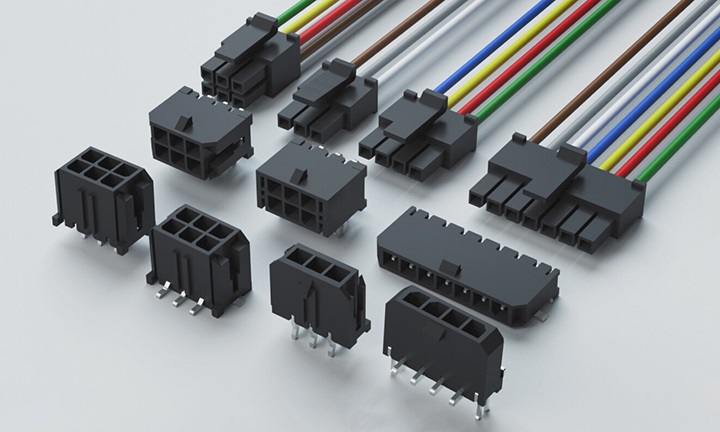

As an important part of industrial robots, connectors have a major impact on industrial robots. Traditional industrial robots have been unable to meet the requirements of industrial manufacturing development. At present, customers have put forward comprehensive requirements such as “wireless, customized and flexible” in the field of industrial robot connection.

1, wireless

Industry 4.0 is driving a major disruptive change need, the wireless interconnect system. In many operating environments, signal commands can only be passed to the robot via a wireless connection. The development of industrial robots will bring huge changes to the connector field, and this new development will bring revolutionary progress to the entire connector.

2, customized

Product “customization” is particularly important in the industrial sector. With the emergence of electronic product diversification and intelligent demand, manufacturers need customized products to meet customer needs, especially in the industrial field, connector manufacturers need to develop new products together with customers to meet their unique shape and function needs.

3, flexible

In addition, industrial automation has also proposed "flexibility" requirements. The gap between the domestic and foreign robot connector and cable industry is first reflected in raw materials, because they require high flexibility, which depends largely on the development and application of raw materials. At present, domestic research and development of raw materials has been weak.

Industrial automation represented by Industry 4.0 will become a new generation of industrial revolution. China will become the largest producer and consumer of industrial robots. Domestic cables and connectors have more home-court advantages. The temporary backward situation requires enterprises to specialize in R&D to break.