Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Photovoltaic inverter is an inverter that converts the variable DC voltage generated by photovoltaic solar panels into alternating current (AC) at the mains frequency. As one of the main components of photovoltaic power generation systems, photovoltaic inverters undertake important functions such as AC/DC conversion, power control, and off grid switching of the entire system, and are key to ensuring the long-term reliable operation of photovoltaic power plants.

In this case, the charging station module power connector developed and produced by TXGA adopts a crown spring terminal structure design, with a large terminal contact area, low contact impedance, a maximum current of 75A, and a maximum voltage of 1000V. The product shell is made of heat-resistant and flame-retardant material, which can work in extreme high and low temperature environments ranging from -55 º C to+125 º C. The product meets the national 3C standard and the EU CE standard.It can achieve stable and reliable high current transmission for photovoltaic inverters.

Acid dew point refers to the condensation temperature of acid dew formed after combustion when the fuel has a high sulfur content. The higher the acid dew point, the more serious the corrosion of acid dew on the steam receiving surface. For combustion engineers, determining the acid dew point temperature of heating furnaces and boilers is the key to improving their thermal efficiency and reducing operational safety hazards. Therefore, the acid dew point meter has become an important tool in the combustion process of fuel-based energy. It plays an important role in equipment safety testing, environmental protection testing and combustion safety testing.

Acid dew point measuring instruments are generally used in process heating furnaces or boilers, so their requirements for heat resistance and explosion protection are very strict. In this case, the M1 circular connector developed by TXGA for acid dew point detection equipment has excellent environmental performance, the working environment is -40℃-+180℃, and it has passed the 48-hour salt spray test. Withstands extreme temperatures and salt spray corrosion.(This product is a customized part, not for sale)

Power transformer is an electrical device that can change the magnitude of AC voltage and is an important component of the power system and power supply system. Through power transformers, current can be increased and decreased to meet different electricity needs. Due to the high transmission current, power transformers usually use a wiring nose at the end of the cable to connect to the PCB board, ensuring a strong connection between the cable and the PCB board to prevent accidents from occurring.

In this case, TXGA provides nut terminals for power transformers, which can be quickly connected to the PCB board by matching them with screws and wires with wiring noses. The maximum transmission current of the product is 120A, and it can withstand working environments ranging from -40 ℃ to 105 ℃. When installing, simply align the circular hole at the top of the wiring nose with the circular hole on the nut terminal, and tighten it with screws to complete the wiring, making the wiring of the power transformer firm and stable, not easy to loosen, and ensuring the safety of the power transformer's use.

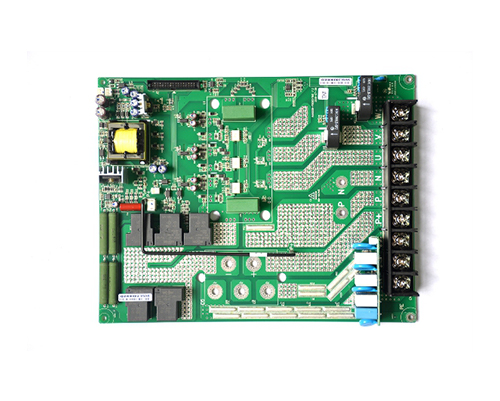

Energy PCBA is a PCBA circuit board applied to energy management equipment, which can remotely and predictively manage and maintain energy equipment, effectively reducing maintenance costs and downtime of energy equipment, and ensuring power generation safety. Due to the special working environment of the energy industry, the reliability requirements for PCBA circuit boards are more stringent.

The FPC/FFC connector developed and produced by TXGA adopts an upper and lower dual contact structure design. The FFC cable can be inserted with the gold finger facing up or down to make contact with the terminal contacts, making the wire layout more flexible. Compared to the front lift lock structure, the rear lift lock design can eliminate the fault of the flap being pulled open when the FFC cable is stretched upwards, reduce the impact of external environments such as falls, vibrations, and impacts on the PCBA board, and ensure interconnection stability.

Energy storage battery refers to the energy storage battery used in solar power generation equipment, wind power generation equipment and other renewable energy sources. It consists of an energy storage battery, a master controller unit (BAMS), a single battery management unit (BMU), and a battery pack-side control and management unit (BCMU). BMS is the management system of the energy storage battery, which is responsible for monitoring the running status of each battery in the battery energy storage unit at all times, and realizes complete communication, monitoring, management, control, early warning and protection functions.

The BMS system of the energy storage battery needs to realize the communication between the host computer and a single energy storage battery through the RJ45 communication interface. The RJ45 series products provided by TXGA for energy storage batteries conform to the Ethernet IEEE802.3 design standard, the network transmission rate is up to 1000Mbps, and multiple ports can be flexibly superimposed according to customer needs to meet the communication needs of energy storage batteries and ensure the safety and reliability of energy storage equipment. run.

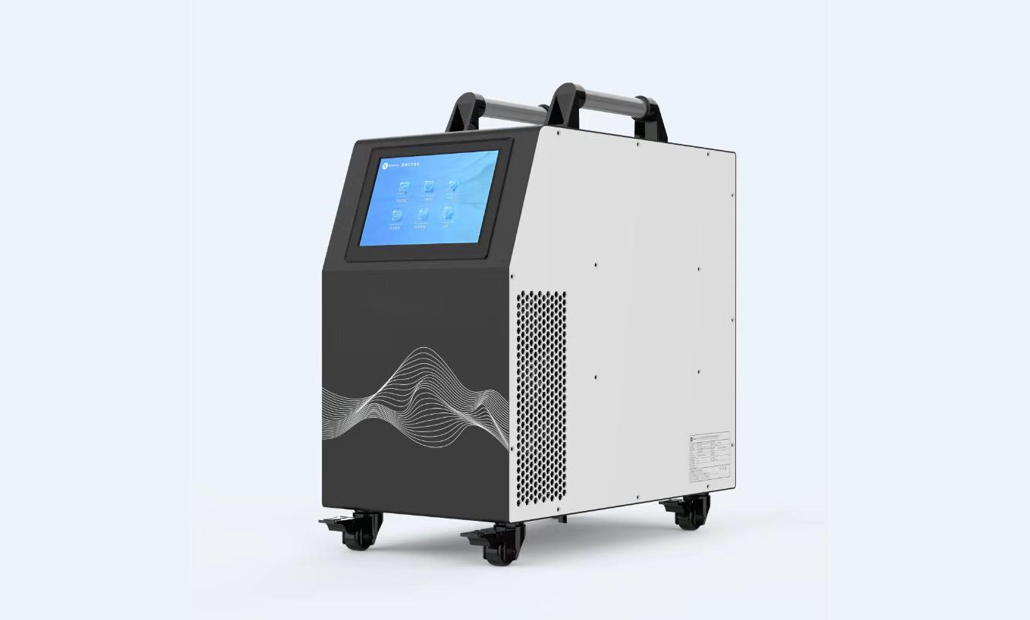

The battery module test system is a kind of equipment specially used to test the charging and discharging performance of various power batteries (lead-acid, nickel hydride, lithium battery, supercapacitor, Hydrogen fuel battery, etc.). With the increasingly widespread application of power batteries, the market has put forward higher requirements for the portability of battery module testing equipment.

In response to the portable requirements of the battery module testing system, in this case, the USB connector developed and produced by TXGA is designed with a right angle elbow structure, which can reduce the PCB board space required for connector installation and achieve a higher degree of integration in circuit board design. The maximum transmission speed of the product is 5 Gbps, and it can be Backward compatibility with USB 2.0 and USB 1.1 devices, making it easier for users to use.

Intelligent power instrument is a widely used intelligent power monitoring instrument in distribution systems, which integrates many functions such as telemetry, remote signaling, display, output, communication, etc. The equipment has the characteristics of high precision and reliability, and is widely used in medium and low voltage transformation and distribution automation systems, industrial automation systems, intelligent switchgear, building automation systems, load control systems, energy management systems, and factory power assessment management.

In this case, the wire to board connector housing provided by TXGA for intelligent power instruments adopts a large locking buckle design, which can ensure stable connector insertion and is not easy to loosen when the instrument equipment vibrates and falls. The lock buckle design can also provide clear tactile feedback during forward locking, ensuring that the user is fully inserted during operation. The product uses PA66 thermoplastic resin, which has good heat resistance and can operate safely in environments ranging from -25 º C to+85 º C, meeting the safety requirements of smart power instrument equipment connectors.