Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Hydraulic lathe is a lathe equipment that achieves automatic machining through a hydraulic system. It usually has 2 to 6 independent tool holders and can process metal materials into high-precision parts with complex shapes through microcomputer programming control. It has been widely used in industrial production. With the advancement of Industry 4.0, hydraulic lathes are typically equipped with advanced automation control systems, making the demand for high-quality data transmission connectors increasingly urgent.

In this case, TXGA provides M12 circular connector X encoding for hydraulic lathes, with a data transmission rate of 10Gbps, supporting CAT6A, and suitable for Category 6A Ethernet cables. And the product adopts an alloy shielding layer, which can comprehensively shield EMI/RFI interference, ensuring that the connector can achieve the best data transmission speed. Meet the high efficiency and stability requirements of data transmission for hydraulic lathes.

Industrial Ethernet switch is an Ethernet switch device applied in the field of industrial control, which can easily connect multiple sensors and actuators in the field layer, achieving simple and efficient field wiring. Widely used in fields such as intelligent manufacturing, industrial automation, smart grids, smart transportation, and smart mines.

In this case, the SPE connector provided by TXGA has a volume of only 20% of RJ45, providing a data transfer rate of 1Gbit/s within a 40 meter range, a transfer rate of 10Mbps within a 1000 meter range, and supporting a power supply of 50W. It can achieve a more compact design for industrial Ethernet switches and achieve long-distance high bandwidth data transmission.

A stable power supply is the key to ensuring the normal operation of electrical appliances. As a type of power switch, rail power supply can accurately control the output of voltage and current, ensuring stable power supply for electrical appliances and effectively avoiding equipment failures caused by unstable voltage. With the increasingly specialized, large-scale, and complex development of modern industrial systems, guide rail power supplies have been widely used in fields such as industrial automation, building automation, and electromechanical equipment.

In this case, TXGA provides wiring terminals for the rail power supply, which are fixed with screws. After inserting wires into the wiring port, users can clamp the metal conductor part of the wires by rotating the screws to ensure a stable and firm electrical connection between the connector and the wires. The available wire gauge for the product is 24-10AWG. Support safe operation in environments ranging from -40 ℃ to+105 ℃, meeting the safety wiring requirements of rail power supply in harsh industrial environments.

Industrial routers are mobile networking devices used in complex environments. It can directly connect industrial equipment for real-time massive data transmission, allowing managers to easily grasp the production and operation situation of factories at different times and locations. Industrial routers usually connect multiple antennas to receive signals from different directions and reduce the impact of signal interference by selectively receiving stronger signals, ensuring that industrial routers can still maintain wireless signal transmission stability and reliability in complex signal environments.

In this case, TXGA provides an RF coaxial connection line for industrial routers, with a cable length of 130mm, a maximum voltage of 335v, a maximum frequency range of 0-6 GHz, a characteristic impedance of 50 Ω, and stable and reliable signal transmission. To meet the application requirements of routers in harsh industrial environments, the working temperature range of connectors can reach -55 º C to+150 º C. Meet the performance requirements of industrial routers for RF connectors.

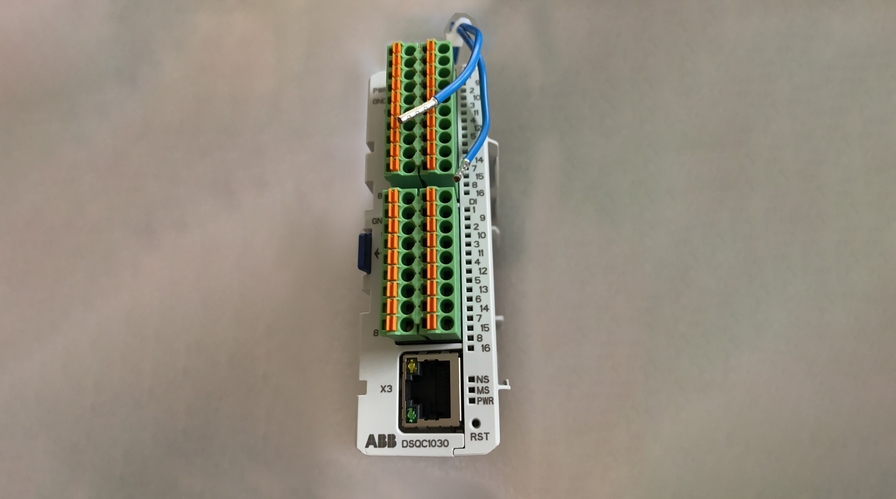

IO expansion module is an important component in the field of industrial automation. Through wiring terminals, the signals from terminal sensors can be transmitted or connected to upper computers such as PLCs between IO modules. At the same time, IO modules can also transmit control signals from upper computers to sensors, achieving unified remote control.

In this case, TXGA provides wiring terminals for IO expansion modules, with stainless steel spring clip structures inside the wire holes. After wire stripping, it can be directly inserted into the wire holes for on-site installation. When pulling out the wire, press the orange pull-out button at the top of the connection terminal to release the spring clip and easily remove the wire, saving a lot of on-site wiring time for IO devices. The product design is compact and can provide reliable interconnection for devices in various high-density connection application scenarios.

CNC machine tool is an automated machine tool equipped with a program control system. When doing homework, simply input the shape and dimensions of mechanical parts as well as the process information of the machining process into the CNC device in a digital form through the information carrier. The CNC machine tool will send out various control signals through decoding and operation processing to control the action of the machine tool, so that the machine tool can automatically process the parts according to the shape and dimensions required by the drawing. Therefore, the data transmission interface of CNC machine tools must have stable and reliable transmission performance.

In this case, TXGA provides a gold plated HMI connector for CNC machine tools, with a data transfer rate of 40MB/s and good compatibility, which can adapt to various operating systems of different CNC machine tools. According to the different final application environments, the SCSI connector housing can flexibly choose different assembly shells to achieve more reliable mechanical and environmental performance, meeting the application needs of high-strength industrial production.

Vacuum pump is a device or equipment that uses mechanical, physical, chemical and other means to extract air from a specific container to obtain a certain range of vacuum state. According to the working principle, the vacuum pump can be divided into two types: gas capture pump and gas transfer pump. At present, vacuum pumps have been widely used in metallurgy, pharmaceutical, chemical, food, electronic coating and other industries.

The three component IDC connector provided by TXGA for the vacuum pump equipment adopts the crimping type with butterfly buckle design. When the product is used together with the flat wire, a large number of wires can be crimped at one time without using any additional tools or welding separately to form a safe and reliable airtight connection. The matched butterfly buckle fittings can also effectively protect the flat cable on the IDC connector to prevent the flat cable from falling off during pulling and vibration. It provides more guarantees for the reliability, stability and service life of the vacuum pump, and ensures that the vacuum pump can operate reliably for a long time under various working conditions.

3D printing, also known as additive manufacturing, refers to the technology of manufacturing three-dimensional solid components from materials based on digital models, stacked point by point, line by line, and layer by layer in the three-dimensional direction. Through the combination of information network technology, advanced material technology, and digital manufacturing technology, 3D printing technology has outstanding advantages such as customization, low loss, and precision manufacturing. It can easily achieve complex designs that traditional machining is difficult to achieve, and finished products can be applied in industries such as medical devices and automobiles.

In view of the high concentration dust environment during the operation of industrial 3D printers, the M16 circular connector developed and produced by TXGA adopts a multi group seal ring design, which can prevent extremely fine dust from entering the connector. The product protection level reaches IP68, effectively reducing the long-term harm of dust to equipment. The main body of the product is made of copper alloy, which can work in the environment of - 40 ℃~+105 ℃, avoiding the failure of the connector in the high-temperature environment of 3D printing, and protecting the high-intensity operation of industrial 3D printers.

Industrial remote control is a wireless device developed for industrial on-site applications, which can control various types of mechanical equipment and industrial production equipment. Through remote control operations, industrial remote controls can effectively increase operator safety and improve production efficiency. With the increasingly widespread application fields, industrial remote controls are often exposed to harsh working environments such as high temperature, low temperature, and humidity, and the market's requirements for the portability and reliability of industrial remote controls have also increased.

In this case,The Micro match connector provided by TXGA for industrial remote controls is a more reliable interconnection solution for portable industrial remote controls. For the harsh working environment of industrial remote controls, the TXGAMicro match connector body is made of PA9T heat-resistant resin material, with a flame retardant grade of UL94 V-0 and a working temperature range of -40 º C to+105 º C, providing a more reliable connection solution for various industrial equipment in harsh environments. The contact spacing of the product is only 1.27mm, effectively saving the PCB board space of the industrial remote control and meeting the portability requirements of the equipment.