During long-term use, the connectors' sockets and pins may experience unavoidable friction and wear on the terminals. The term 'plug and unplug life' often refers to wear resistance to a certain extent. How should users reduce the wear of connectors and extend their service life during use?

Avoid frequent plugging and unplugging: Try to reduce the frequency of frequent plugging and unplugging of connectors, as frequent plugging and unplugging can increase wear and tear on the connector area.

Correct insertion and removal: When inserting and removing connectors, ensure that the plug and socket are correctly aligned, and then gently but firmly insert or remove them. Avoid skewed insertion and removal to reduce wear on the connector area.

Prevention of vibration and impact: Avoid applying excessive vibration or impact near the connector, which helps to prevent loosening or damage to the joint area.

Cable management: Ensure that cables near connectors are properly managed, avoiding excessive pulling or bending of cables, and reducing mechanical stress on joints.

Regular inspection and maintenance: Regularly inspect the appearance of connectors and joints for signs of wear. If problems are found, take timely corrective measures.

Guiding structure: Some connectors are designed with guiding structures to ensure correct alignment between plugs and sockets, reducing friction and wear during insertion and removal.

Avoid excessive use of force: When inserting and unplugging connectors, avoid using excessive force to avoid unnecessary wear and tear.

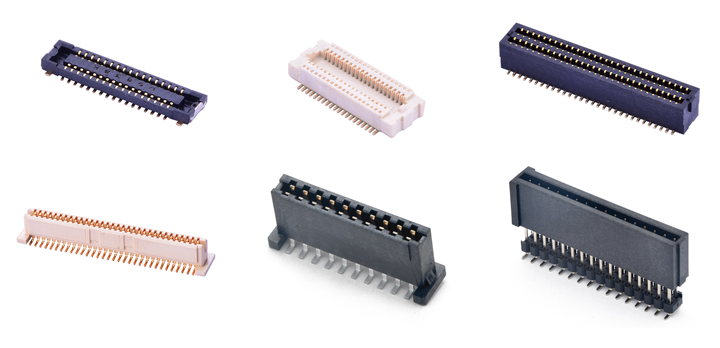

To ensure the safety of connector use, during the process of selecting connectors, it is also necessary to communicate fully with the connector manufacturer to confirm the plug and unplug life and environmental suitability of the purchased product, in order to minimize connector loss as much as possible. TXGA is one of the leading domestic connector manufacturers with professional and mature production processes. You only need to propose the final application requirements and budget, and TXGA can provide a complete one-stop solution to assist in your product development. Go to TXGA [Product Center] to learn more.