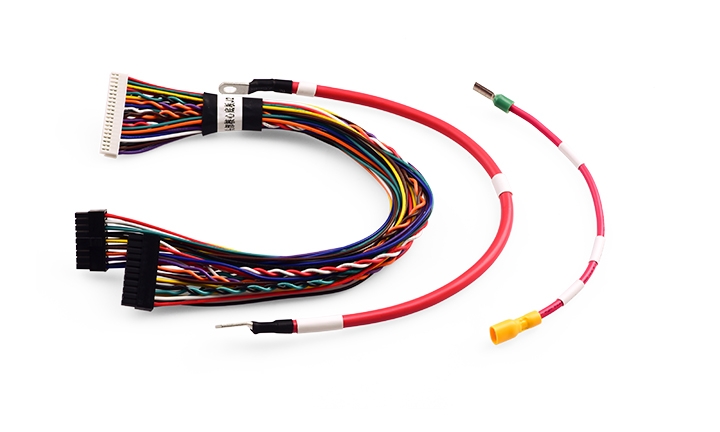

In modern electronic devices, wire harnesses are an essential and important component. While providing and distributing power to various electrical systems, wire harnesses also serve as signal transmission media between components. In the riveting process of wire harness terminals, to ensure riveting quality and reliability, multiple aspects must be considered:

1、 Terminal selection. Select suitable wiring harnesses and terminals according to application requirements to ensure mutual matching and meet current and voltage requirements.

2、 Terminal preparation. Before riveting, ensure the cleanliness and surface smoothness of the terminals and wire harness conductors. Ensure that there are no oxides, dirt, or coatings to ensure good electrical contact.

3、 Tool selection. Choose appropriate riveting tools, such as riveting presses, crimping pliers, etc., and use the correct crimping molds.

4、 Crimping process. Insert the wire harness conductor into the terminal slot and use a riveting tool to apply appropriate pressure for riveting. It is necessary to ensure even crimping to avoid situations such as inadequate crimping or excessive force damaging the terminals.

5、 Visual inspection. After completing the riveting process, a visual inspection is required to ensure that the terminal blocks are tightly connected to the conductors without any looseness or misalignment.

6、 Electrical testing. Electrical testing using testing equipment generally includes resistance testing, insulation testing, and current load testing.

TXGA is one of the leading domestic connector manufacturers with professional and mature production processes. We have been providing reliable, professional, and stable connector products to the industry for over a decade. Realize various personalized needs of customers. Need wiring harness terminals to enter TXGA [Product Center].