Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer:连接器 Posted time {{1716252837000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:84

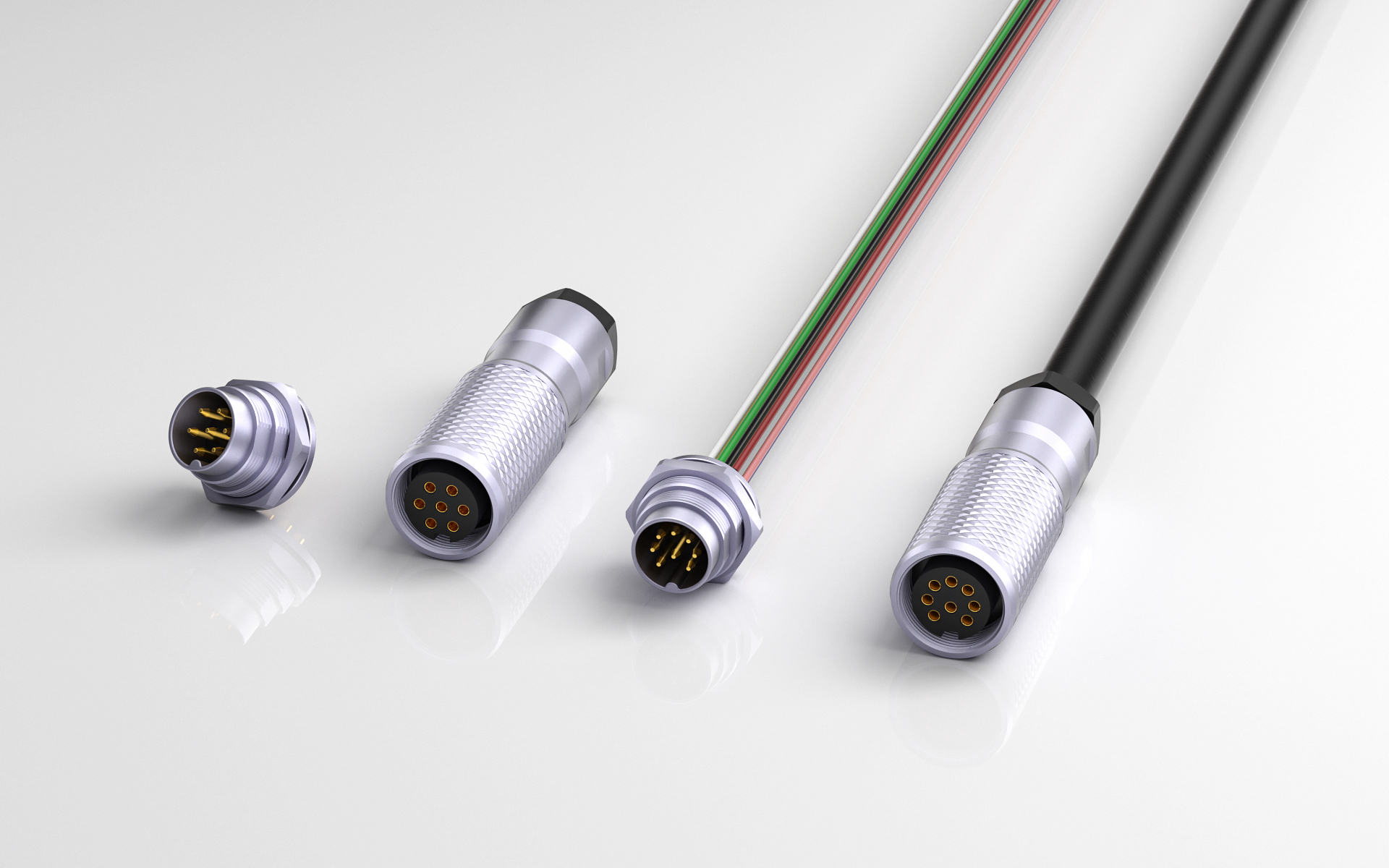

The high and low temperature resistance of a connector refers to its ability to maintain functional stability at different temperatures. Excessive high temperatures generally lead to a decrease in connector strength or even softening, while excessively low temperatures can increase the brittleness of the connector and make it prone to brittle fracture. How to optimize the high and low temperature resistance performance of connectors?

1. Choose high-quality materials that are resistant to high and low temperatures: the metal part of the connector can be changed to materials such as stainless steel, copper alloy, zinc alloy, etc., while the plastic part can be changed to materials such as outdoor engineering plastic and silicone rubber.

2. Optimize structural design: Reasonably arrange the pins and solder joints of the connector to reduce thermal and mechanical stress; Optimize the structural design of connectors to improve their heat dissipation performance.

3. Environmental control: In extreme high and low temperature environments, the impact of environmental temperature on connectors can be reduced by introducing cooling systems or insulation systems. Setting up cooling fans and fins to help connectors efficiently dissipate heat; Alternatively, an insulation layer can be installed outside the device to reduce the direct impact of external temperature on the connector.

TXGA is one of the leading domestic connector manufacturers with professional and mature production processes. You only need to propose the final application requirements and budget, and TXGA can provide a complete one-stop solution to assist your device research and development. Go to TXGA [Product Center] to learn more.