Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer:连接器 Posted time {{1724235642000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:128

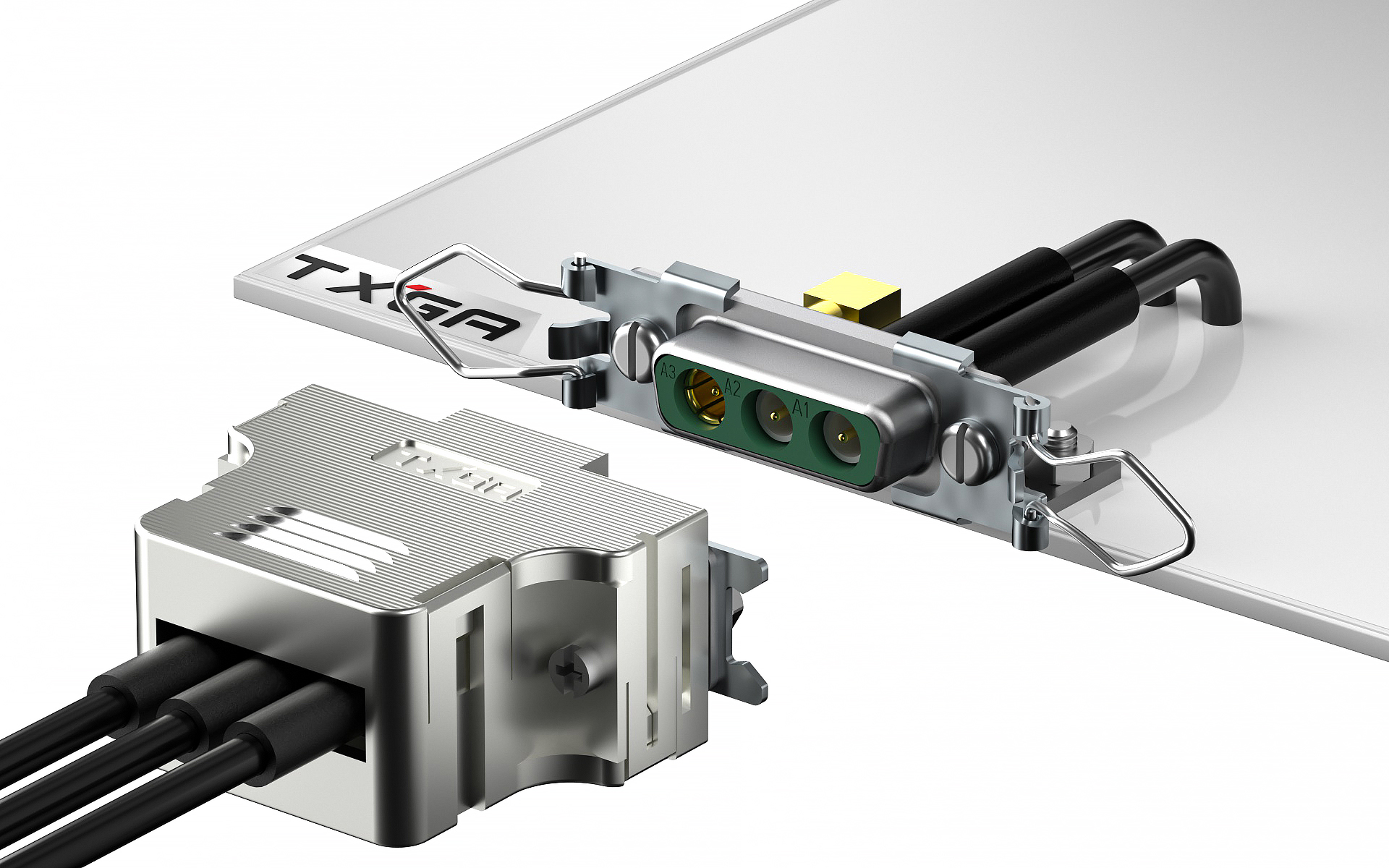

Electronic connectors typically consist of four parts: contacts, insulators, housing, and accessories. Among them, there are various forms of attachments, including locking blocks, locating pins, guide pins, connecting rings, rotating bars, sealing rings, sealing plugs, screws and nuts, spring clamps, etc. When customers request special application requirements that cannot be met by standard parts, connector manufacturers usually enhance the required connector performance by adding accessory designs to the product.

When the connector is used in a strong impact vibration environment for a long time, the insertion and extraction force of the connector body is difficult to ensure the contact stability of the terminals. Therefore, locking blocks, connection rings, screws and nuts can be designed to enhance the fixing force between the male and female heads of the connector and avoid accidental loosening. When connectors are used in harsh environments such as dust and humidity, in order to prevent dust and water vapor from entering the interior of the connector, accessories such as sealing plugs and sealing rings are usually added to improve the protective performance of the connector.

TXGA is a leading domestic connector manufacturer with mature and professional production processes. You only need to provide the final application requirements and budget, and TXGA can offer a complete one-stop solution to assist in the development of your equipment. Enter TXGA [Product Center] to learn more.