Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer: 微D形连接器 Posted time {{1733212788000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:35

The trend towards miniaturization and lightweighting is becoming increasingly prominent, and the requirements for connectors in the new generation of electronic devices are becoming more stringent. They not only require compact structures, but also reliable performance.

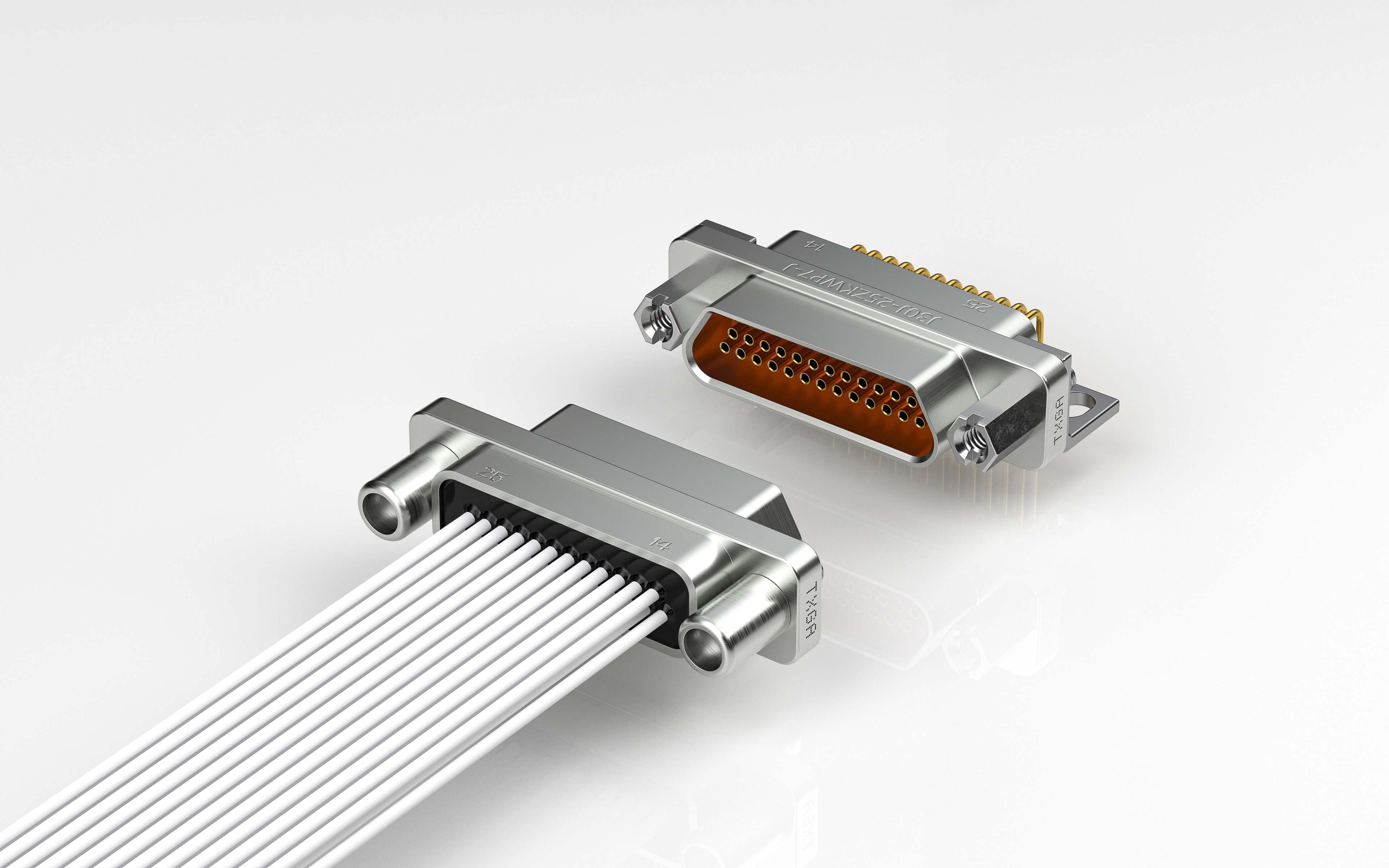

The TXGA micro D-shaped connector, with its compact size, lightweight, and excellent reliability, can be flexibly laid out in harsh environments and small spaces. This connector is designed specifically for high-density current and signal transmission, making it an ideal choice for compact devices.

Compact size, flexible application

The contact spacing of TXGA micro D-shaped connector is only 1.27mm, and the required installation space is only half of that of standard D-shaped connector. This feature enables it to easily adapt to various electrical equipment with limited space, meeting the interconnection needs of compact devices.

Anti vibration, anti impact

The product terminal adopts a twisted wire pin design to ensure stable contact. In tests with vibration frequencies ranging from 10Hz to 2000Hz and acceleration up to 196m/s ², the instantaneous interruption time does not exceed 1 μ s. In the impact test with an acceleration of up to 735m/s ², it also performed well, and the instantaneous interruption time did not exceed 1 μ s. This fully demonstrates the high reliability of the connector in impact vibration environments.

Mechanical connection, safe and reliable

The connector is equipped with screw structures on both sides, effectively preventing connection interruptions caused by environmental vibrations or accidental pulling. This design ensures the stability and safety of the electrical system of the equipment, allowing it to operate stably even in complex environments.

Product specifications and selection

The contact spacing is 1.27mm, and the number of cores can be selected from 9, 15, 25, or 37 to meet the needs of different application scenarios.

application area

Navigation system

Radar system

medical apparatus and instruments

robot

UAV