Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

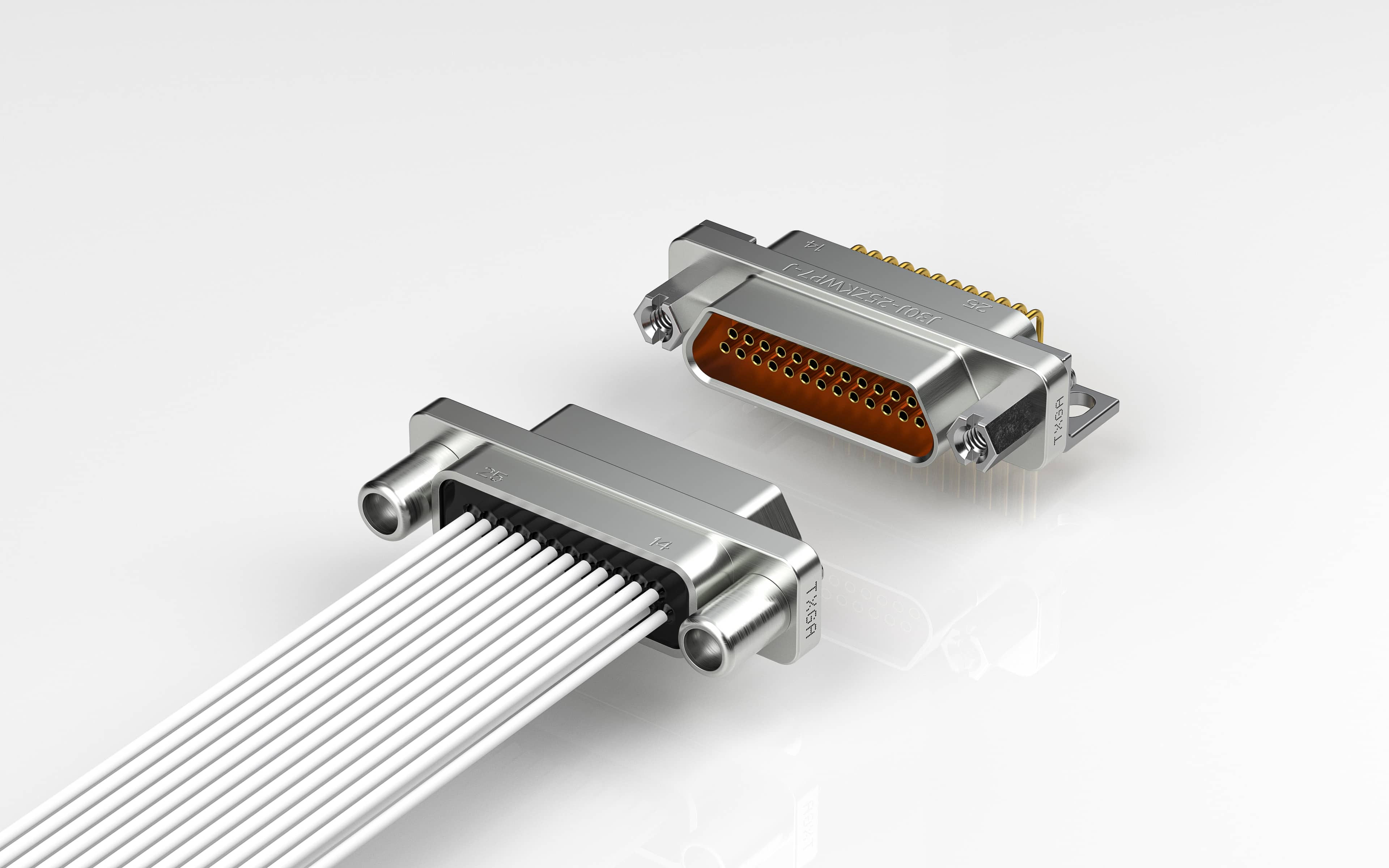

Writer:微D形连接器 Posted time {{1737622252000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:50

In connector technology, twisted wire pin connector is usually called Fried Dough Twists pin. As the core contact element of the connector, the twisted wire pin has a sophisticated and complex structure: it is composed of two layers of copper alloy wire twisted in opposite directions, with the inner layer containing three fine wires and the outer layer usually having seven or nine wires. These fine wires are tightly connected at both ends through welding technology, forming a whole, with an overall shape like a drum shaped structure with a handle.

Of particular importance is the design of a hollow bulge near the needle end of the twisted wire plug. When the pin is inserted into the rigid socket, this bulge will be subjected to positive pressure, resulting in elastic deformation. The specific manifestation of deformation is that the bulging area is compressed radially towards the axis, while extending along the spiral direction in the axial direction. This deformation promotes the formation of multiple contact points between the pins and sockets, ensuring stable and reliable electrical contact.

The unique structural design of twisted wire pins not only endows it with excellent vibration and impact resistance, but also provides the possibility for the ultra miniaturization of connectors. It is precisely based on these advantages that twisted wire pin connectors are widely used in precision electronic devices such as micro D-shaped connectors, becoming a key component for achieving efficient and stable electrical connections.